Hanrun Paper B604 DTF Powder Shaker With Automatic Powder Recycling System

Categories DTF printers, Hanrun Paper

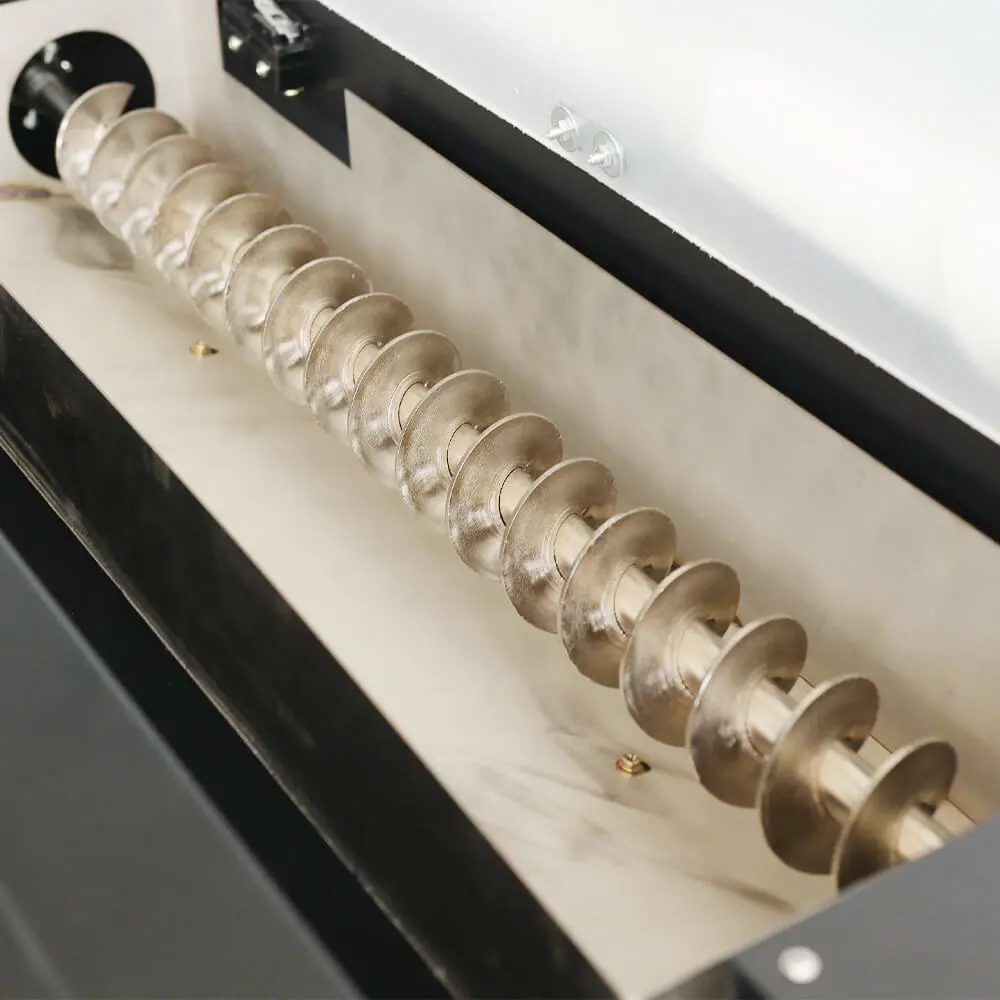

In order to further improve the efficiency of the DTF printer, we have upgraded the powder shaker to solve the tedious manual powder recovery process in the past. An automatic powder recovery system has been installed inside the DTF powder shaker. A filter has been added to filter out unnecessary dust and dust impurities, so that the recovered hot melt powder is cleaner. It can effectively improve the utilization rate of hot melt powder, making the machine operation more time-saving and labor-saving than before, and you can get the maximum benefit in the simplest way. Our B604 DTF Shaker machine can perfectly work with PRO-A600 Dual Head DTF Printer.

| Model | B604 |

| Nominal voltage | AC220V,50/60Hz AC110V,50/60Hz |

| Rated power | 6.8KW |

| Applicable machines | Dual Head DTF Printer |

| Applicable Industries | Clothing stores, printing houses, clothing factories, traders and processors, etc. |

| Media Width | 0-600mm |

| Main components | Intelligent temperature controller, main control board display screen, motor, main board |

| Weight | Gross weight: 428KG Net weight: 313KG |

| Dimensions | 2240mmX1180mmX 1220(mm) |

| Packing Dimensions | 2280mmX1170mmX1385 (mm) |

| Work environment | 20-30°C 45-70%RH |

| Warranty | The whole machine is guaranteed for one year, *excluding shipping |

- Automatic powder recycling: you can add more powder at once; Powder over 5kg can last 1-2 days.

- Extended tunnel design: longer tunnels can be used with faster printers for higher output efficiency

- High-end control panel: smart thermostat, adjustable powder distribution intensity and belt speed,

- Labor saving: high-efficiency powder agitator and drying intensity adjustment according to printing speed